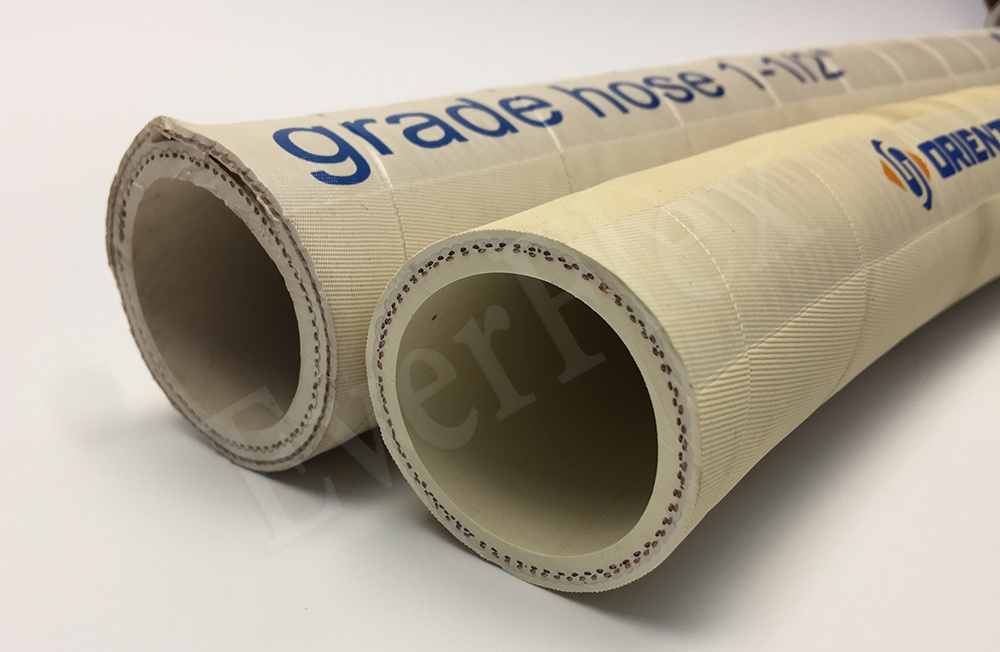

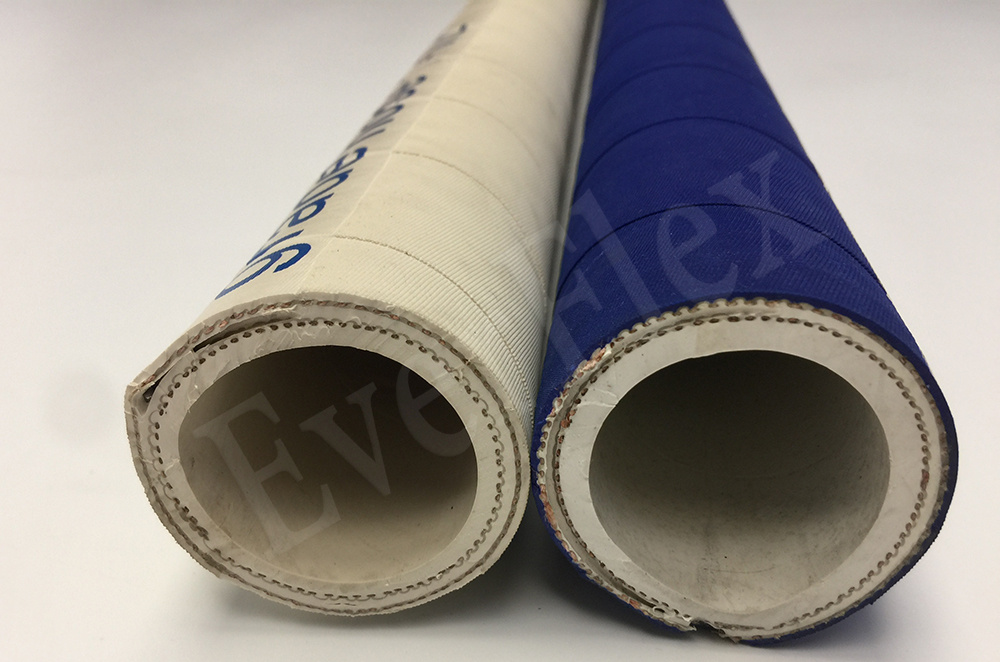

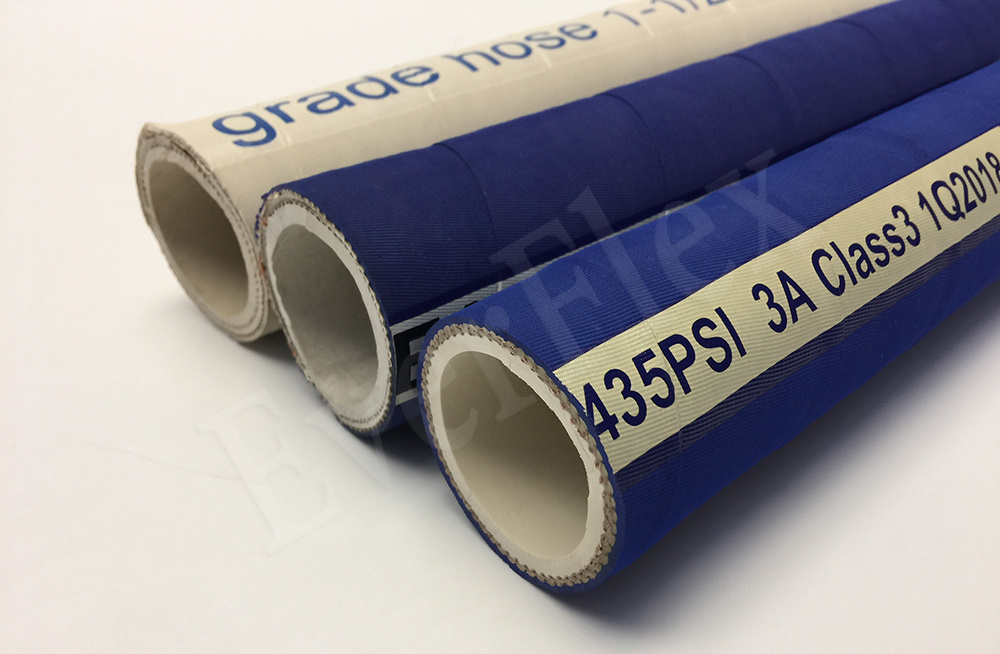

Food grade hoses play vital roles in both household and industrial settings. From silicone coffee machine tubes to rubber dairy transfer lines and PVC wine hoses, these specialized conduits ensure safe product handling. However, several common problems can compromise their performance and safety.

1. Surface Cracking

Symptoms: Visible cracks on hose exterior

Primary Cause: Flexing in cold environments

Solution:

Use cold-resistant hose materials

Avoid bending below recommended temperatures

Store properly in climate-controlled areas

2. Bubble Formation

Symptoms: Blistering on outer surface

Root Causes:

Substandard manufacturing quality

Improper operating pressures/temperatures

Prevention:

Source hoses from certified suppliers

Follow manufacturer’s pressure ratings

3. Internal Leakage

Symptoms: Fluid seepage without visible breaks

Mechanism:

High-velocity flow erodes inner lining

Exposed reinforcement layers leak

Corrective Action:

Inspect for internal abrasion regularly

Replace at first signs of weeping

4. Surface Degradation

Symptoms:

Outer layer hardening

Micro-crack networks

Ozone discoloration

Progression:

Natural rubber oxidation begins

Protective layer forms and thickens

Flexibility decreases

Cracks develop during use

Critical Step: Immediate replacement when detected

Proactive Maintenance Tips

Conduct regular visual inspections

Monitor for changes in flexibility

Track service hours for aging hoses

Establish preventive replacement schedules

For comprehensive food grade hose solutions, Everflex offers:

NSF/FDA-certified hose options

Material compatibility guidance

Failure analysis services

Custom configuration support

Our engineers can help you:

Select the optimal hose material

Design proper maintenance protocols

Troubleshoot recurring issues

Contact our technical team for personalized assistance with your food grade hose challenges. We provide actionable solutions to extend service life while maintaining strict hygiene standards.