Steam hoses are purposefully crafted for the conveyance of high-pressure steam, with steam temperatures often exceeding 200℃. Any leakage can precipitate severe safety incidents, making proper usage crucial for safeguarding personal well-being.

Conversely, incorrect use and maintenance can introduce significant security threats. Let’s explore some of the improper operations associated with steam hoses:

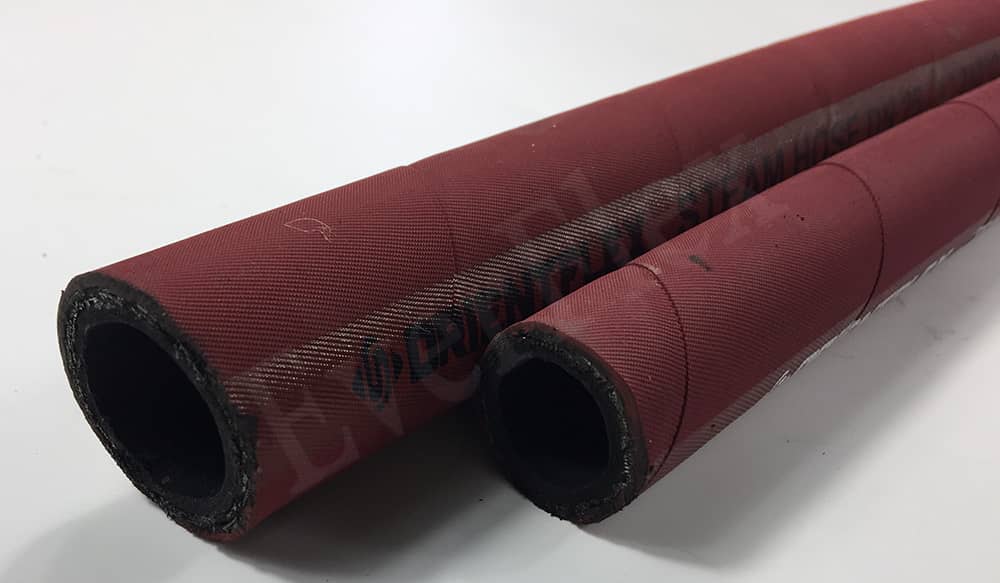

Substituting a Hydraulic Hose for a Steam Pipe

Hydraulic hoses can endure high pressure, yet they are comparatively bulky. More critically, they lack the capacity to withstand high temperatures. This makes them prone to steam leaks and scalding accidents. Consequently, it is essential to employ dedicated steam hoses for transporting steam or high-temp water.

Replacing Steam Hoses with Low-Pressure, Low-Temperature Rubber Hoses

This practice poses a massive safety hazard to operations. Additionally, the financial cost of frequently replacing pipes is substantially higher than that of using specialized steam hoses.

Randomly Using Hoops or Camlocks Instead of Dedicated Steam Hose Joints

When dealing with pressures exceeding ten kilograms, relying on just a few thin steel wires wound and tightened is extremely dangerous. It creates a significant safety vulnerability.

Neglecting Regular Inspection and Repair of Steam Hoses

Steam hoses are susceptible to wear and tear. Regular checks should be carried out to detect any cracks, bubbles, or damage. If issues are identified, prompt repair or replacement is necessary. Some individuals seldom maintain the hoses, endangering themselves and others. Others continue using steam hoses past their expiration, refusing to replace them even when problems arise. Such actions carry great risks.

These are the common errors people make when using steam hoses, all of which can lead to serious consequences. Therefore, it is imperative to place a greater emphasis on routine inspections.