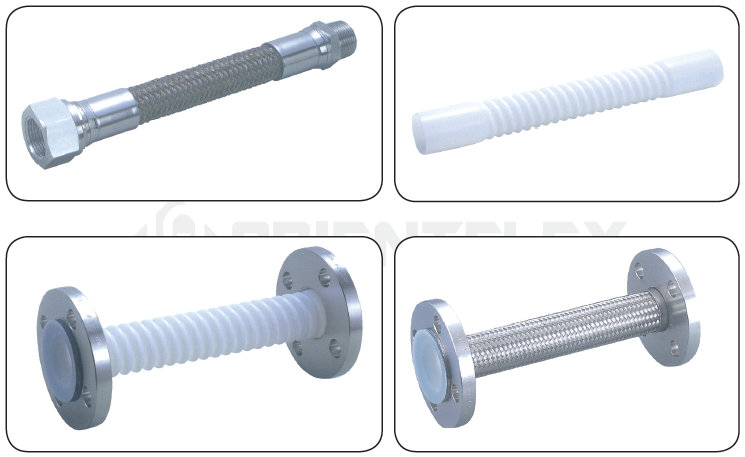

PTFE Hose

PTFE is the “King” among all the plastics. Thus the Teflon Hose also has great properties.

Heat resistance

It can constantly work in 260℃ for long term and even 300℃ shortly. Besides, it has excellent low temperature resistance. Thus PTFE is widely used to produce electric appliance, components and insulated wires.

Chemical property

Teflon hose has excellent resistance to general chemicals. It resists acid or alkali oxidant agent even at high temperature condition. So PTFE fittings, PTFE lining, PTFE sealing and PTFE sleeve is quite suitable for chemical industry.

Electrical property

The molecular structure PTFE is nonpolar, so it’s suitable for high frequency insulation material. The permittivity and dielectric loss is low and stable in wide frequency range. Besides, it is immune to sunlight and humidity. Thus, it’s very suitable for wires and insulation sleeve.

Corrosion resistance

In normal conditions, PTFE hose assemblies have extremely low solid friction coefficient and it will not peristalsis. Besides, it almost not bond with other materials, so it can transfer viscous liquid in automobile manufacture and mechanical industry.

Why Everflex PTFE Hose IS Great

Raw material

We purchase the high quality PTFE material from home and import the best raw material from foreign countries. Because we know it clearly that raw material determines the quality of hose directly.

Extrude

The inner tube comes out from the extruding machine, then it will enter a PU duct hose. This is to protect the inner hose. Thus, it is immune to the dirty and dust in the air.

Test

After the inner tube molding, we will take several tests to guarantee its quality. First is the air tightness test. Connect the hose into the test machine, then put into pressure, which is max 2.3Mpa. The pressure charge will last 10 second and remain the pressure for 1 minute. In the meantime, there will be figure on the machine. If the figure becomes small, that means the air tightness is bad. While if there is no change, that means the air tightness is good.

Another is air leakage test. Insert a steel rod into the inner tube, then use a special tool slip on the tube. If there is just small electricity between the tool and hose, that means there is not leakage. But if there is sharp reaction with fire, than means there is leakage on the fire point.

Besides, there are many other tests like insulation test, tensile strength test and cracking test. After these test, we can see the inner tube is high quality.