When choosing hydraulic hose, there are several crucial factors you need to take into account:

Pressure

Firstly, think about the pressure rating of the hose. It must be capable of handling the max working pressure of the system. If the hose can’t withstand the pressure, it’s likely to fail. Then this will lead to leaks and potential damage to the equipment.

Temperature Range

The temperature range of the hydraulic system is another vital aspect. The hose should be able to operate smoothly within the minimum and maximum temperature limits of the system. Extreme temperatures can cause the hose material to degrade, affecting its performance and lifespan.

Fluid

The compatibility of the hose material with the fluid in the system is essential. Some fluids have the potential to make the hose deteriorate or weaken over time. Eventually, this could result in the hose failing. So, always ensure the hose and fluid are a good match.

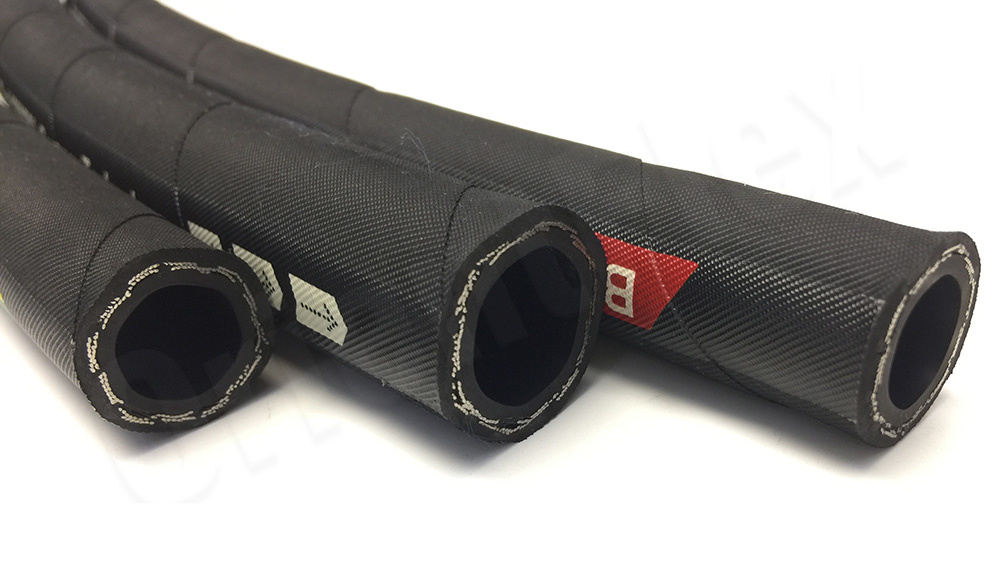

Hose Size

Selecting the appropriate size of the hose is based on the flow rate and pressure of the system. If you use a hose that’s too small, it can cause an excessive pressure drop, leading to poor system performance. On the other hand, opting for a hose that’s too large might be unnecessarily costly.

Bend Radius

The hose should have a small enough bend radius that allows it to flex without kinking or getting damaged. The bend radius depends on the hose’s structure and size. A proper bend radius ensures the hose can be routed efficiently without compromising its integrity.

Length

The length of the hose needs to be determined by the distance between the machines it connects. Picking a hose that’s too long increases the risk of kinking, while a short hose might limit the system’s flexibility. Strike the right balance to optimize the setup.

Work Condition

The environment where the hose will be used matters a great deal. For instance, if it’s exposed to sunlight or chemicals, it can age prematurely. Consider any potential environmental factors that could impact the hose’s durability.

Standards

Make sure the hose complies with relevant standards like SAE, ISO, EN, and others. Meeting these standards is a good indication of quality and reliability.

By considering these factors, you can pick the right hydraulic hose for your work. Moreover, having a reliable supplier is equally important. Try to go for a well-known brand to ensure the quality is up to par. Everflex is such a supplier that could meet your needs. Contact us now to learn more.