In the previous article, we explored the materials of chemical – resistant hoses. Now, I’ll tell you about the wall thickness and production aspects of chemical transfer hoses.

Wall Thickness: A Crucial Parameter

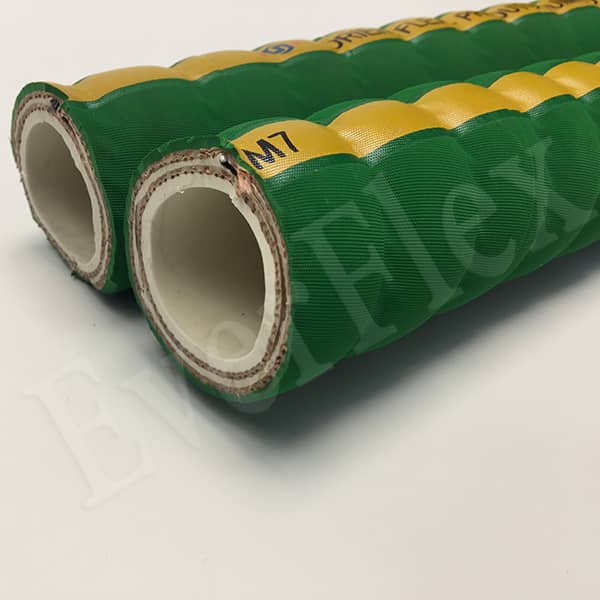

During operation, the inner walls of hoses face high – pressure impacts from the inertia of moving liquids or gases. A hose with a thin wall is at risk of bursting, which can lead to chemical leaks, pollution, and even harm to people. So, when choosing an acid – resistant hose, picking the right wall thickness is essential for pipeline safety.

Technical Challenges in Chemical-Resistant Flexible Hose Production

Take PU hoses as an example. During production, the proportion of synthetic materials must be precise. Otherwise, the hose’s strength and hardness will suffer. Additionally, tight control over errors in the inner diameter and wall thickness is necessary to ensure product quality.

In summary, solvent – resistant hoses are vital in chemical production. When selecting and using them, factors like material and wall thickness should be considered. Moreover, strict quality control is a must. Only then can chemical hoses be safe and reliable.